What is WIZ?

WIZ is an industry-leading CAM system for Wire EDM developed for precision parts machining, Die and Mold and stamping.

The biggest feature is that machining conditions can be set using the same database as the machine used,

and the dry run simulation of NC programs with machining conditions and offsets can be performed on WIZ.

This eliminates the need to add machining conditions and confirm the shape on the machine side, which is effective in shortening setup time.

Please give it a try.

Create machining programs instantly

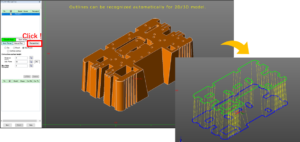

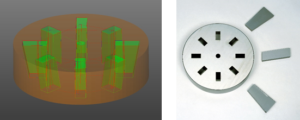

Automatic extraction of wire machining parts

Wire cut part is directly recognized from 3D model (Parasolid, IGES).

Conversion to 2D data is no longer required.

It recognizes die, punch or open shape with one click and automatically extracts machining parts including plate thickness and taper angle.

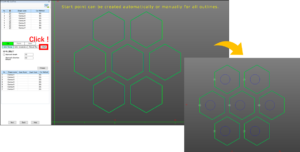

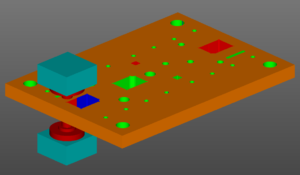

Automatic generation of starting holes

One-click to generate starting holes and approach positions suitable for the machining part.

In addition, the coordinates of the starting holes can be output and used for the machining of starting holes.

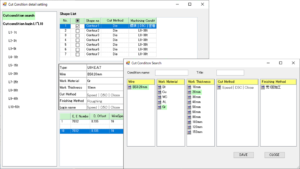

Optimum machining condition setting with the same database as the machine

All machining conditions (more than 1000 types) of MAKINO Wire EDM are built-in.

Anyone can select the optimum machining conditions on the search screen.

In addition, frequently used machining conditions can be registered and used as templates.

Correspondence to various machining contents

Programming such as taper, 4 axis, coreless machining etc. are possible.

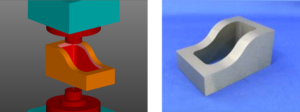

Taper machining

Slide core is also supported.

4 axis machining

4 axis machining corresponding to the circular interpolation output is equipped as standard.

Coreless machining

Generate coreless machining path with one click.

Rich simulation capabilities

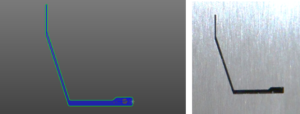

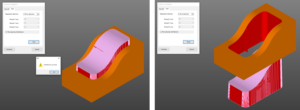

Intuitive machining simulation is possible in 3D shape with offset added.

The direction of core pulling out for 4 axis machining can also be confirmed by simulation.

The shape after simulation can be dimensioned as a stock model.

It is also possible to check the details machining shape by displaying the cross-sectional surface.

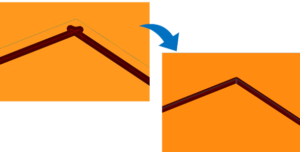

Automatic correction of offset interference

Offset interference is automatically detected and can be corrected.

Offset interference is detected during simulation and automatically corrects machining path.